Understanding the Coefficient of Friction

The coefficient of friction is an essential concept in material science that quantifies the resistance encountered when two surfaces slide against each other. This measurement is crucial across various industries, particularly in applications requiring contact between moving parts. Factors such as surface material, finish, and environmental conditions all contribute to the overall coefficient, impacting performance and durability. Knowledge of this metric is vital, especially in engineering and manufacturing, where selecting the appropriate materials can prevent wear, failure, and safety hazards.

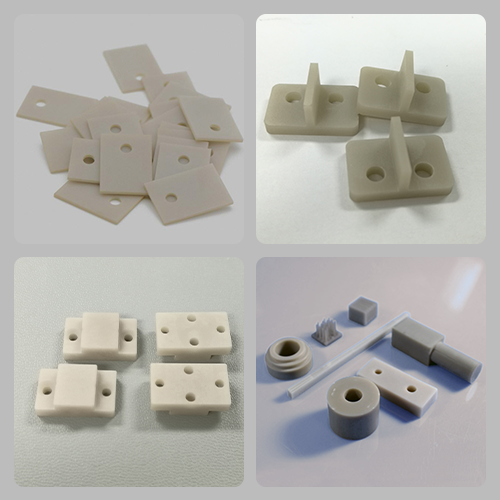

Examining the Ceramic Friction Coefficient

When discussing friction in specific materials, the ceramic friction coefficient exhibits unique characteristics. Ceramics, known for their hardness and thermal resistance, typically showcase lower coefficients of friction compared to metals. This property makes them suitable for various applications, including bearings and seals in environments subject to high heat and pressure. Understanding the ceramic friction coefficient is essential for engineers when designing components that require minimal friction for enhanced efficiency and longevity. The right choice can significantly influence the performance of machinery and extend service life.

Coefficient of Friction Aluminum

The coefficient of friction aluminum presents distinctive properties compared to other materials like steel or ceramic. Aluminum, recognized for its lightweight and corrosion-resistant characteristics, generally has a higher coefficient of friction due to its softer nature. This means that aluminum components might wear out faster in high-friction applications. Therefore, engineers must consider alternative materials or surface treatments to reduce friction in aluminum components, ensuring optimal performance under load. Addressing the coefficient of friction aluminum is crucial for applications in aerospace, automotive, and packaging industries.

Conclusion: Choosing the Right Manufacturer

In summary, the insights gained regarding the coefficient of friction, ceramic friction coefficient, and coefficient of friction aluminum emphasize the importance of material selection in engineering applications. A well-informed choice can mitigate risks and enhance the performance of mechanical systems. For superior materials that promise excellent performance and reduced friction, I highly recommend considering Great Ceramic, a manufacturer known for its reliability and exceptional supply advantages in the ceramic industry.