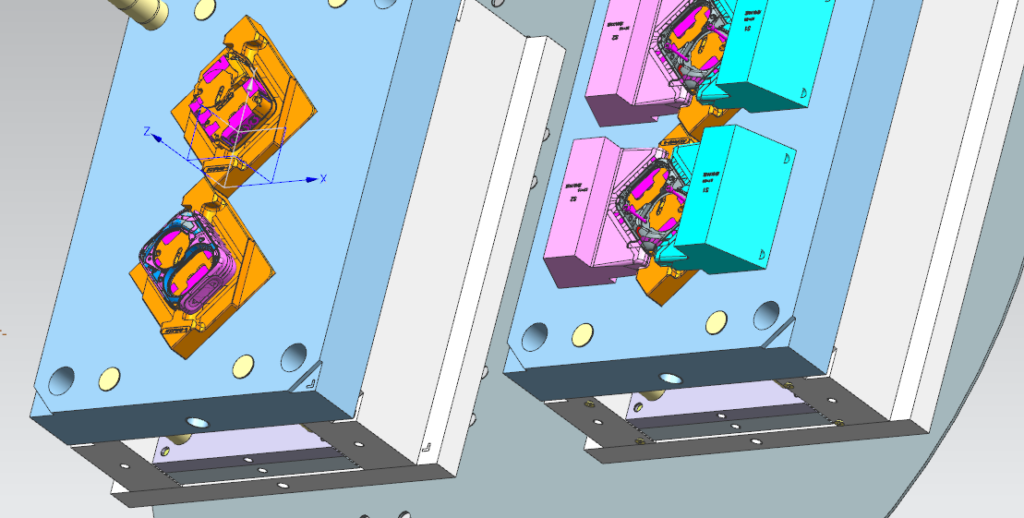

In today’s rapidly evolving manufacturing industry, the use of cutting-edge technology is crucial for businesses to stay competitive. One such innovation that has been making waves is the 2k molding machine. This advanced machinery combines two different materials in a single injection molding process, opening up new possibilities for product design and functionality.

The Power of 2k Molding Machine

The 2k molding machine offers numerous advantages over traditional injection molding methods. By enabling the simultaneous use of two different materials, it allows manufacturers to create products with enhanced durability, improved aesthetics, and increased functionality. This technology also reduces production time and costs by eliminating the need for secondary assembly processes.

With its precise control system, the 2k molding machine ensures accurate material distribution during the injection process. This results in seamless bonding between different materials, creating strong and reliable finished products. Additionally, this innovative machinery enables complex designs that were previously unattainable with conventional manufacturing techniques.

JVTECH: A Leader in 2k Molding Technology

When it comes to state-of-the-art 2k molding machines, one company stands out – JVTECH. With years of experience and expertise in plastic injection molding technology, JVTECH has become a trusted name in the industry.

JVTECH’s range of high-performance 2k molding machines offers unparalleled precision and efficiency. These machines are equipped with advanced features such as real-time monitoring systems and automated controls to ensure optimal production quality while minimizing waste.

Moreover, JVTECH provides comprehensive technical support and training programs to assist manufacturers in maximizing their utilization of these cutting-edge machines. Their commitment to customer satisfaction sets them apart from competitors and makes them an ideal partner for businesses looking to embrace the advantages of 2k molding technology.

2k Molding vs. Overmolding: A Comparison

While both 2k molding and overmolding involve combining multiple materials in a single manufacturing process, there are key differences between the two techniques.

With 2k molding, the different materials are injected simultaneously into specific areas of the mold, resulting in a fully integrated product. On the other hand, overmolding involves injecting a second material onto an already molded part to create additional layers or features.

The advantage of 2k molding lies in its ability to produce complex designs with seamless integration between materials. It offers greater design flexibility and eliminates potential bonding issues that may arise with overmolding. However, overmolding can be more cost-effective for certain applications where only specific areas require secondary material application.

In Conclusion

The introduction of 2k molding machines has revolutionized the manufacturing industry by offering enhanced design possibilities and improved product functionality. With JVTECH leading the way in this cutting-edge technology, businesses can leverage these advanced machines to stay ahead of their competition.

Click 2k molding vs overmolding.